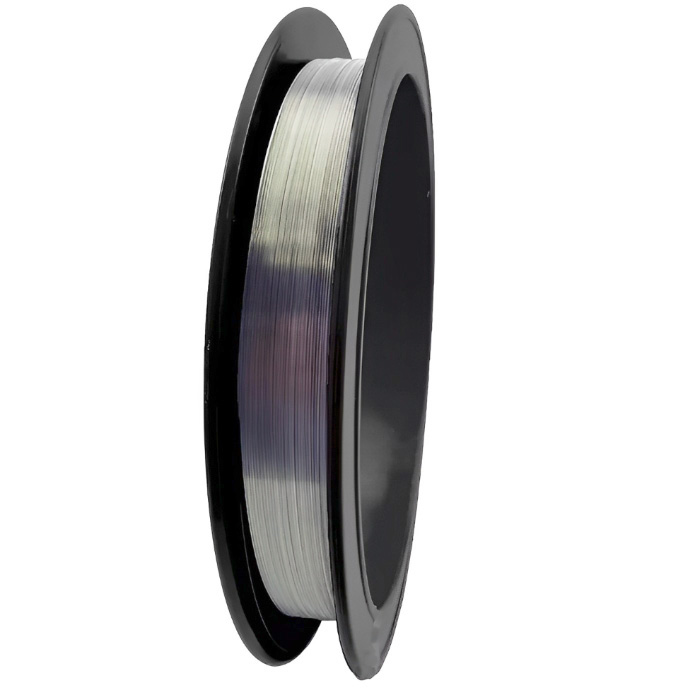

High Quality Purity 99.95% Tungsten Wire

Jinis lan Ukuran

W-kabel ireng biasa ditutupi grafit.Sawise grafit dibusak iku luster metalik.

| sebutan | Kandungan Tungsten | Isi Unsur Najis | |

| Total | Saben | ||

| WAL1, WAL2 | ≥99,95% | ≤0,05% | ≤0,01% |

| W1 | ≥99,95% | ≤0,05% | ≤0,01% |

| W2 | ≥99,92% | ≤0,08% | ≤0,01% |

| Cathetan: Kalium ora diitung ing isi impurities. | |||

Toleransi diameteripun (%):

| Dhiameter (μm) | Bobot (mg/200mm) | Bobot (mg/200mm) Toleransi (%) | Toleransi Diameter (%) | ||||

| Kelas 0 | kelas 1 | kelas 2 | Kelas 0 | kelas 1 | kelas 2 | ||

| 5≤d≤12 | 0,075~0,44 | - | ±4 | ±5 | - | - | - |

| 12 | >0.44~0.98 | - | ±3 | ±4 | - | - | - |

| 18 | >0.98~4.85 | ±2 | ± 2.5 | ±3 | - | - | - |

| 40 | >4.85~19.39 | ± 1.5 | ± 2.0 | ± 2.5 | - | - | - |

| 80 | > 19.39~272.71 | ± 1.0 | ± 1.5 | ± 2.0 | - | - | - |

| 300 | > 272.71~371.79 | - | ± 1.0 | ± 1.5 | - | - | - |

| 350 | - | - | ± 1.5 | ± 2.0 | ± 2.5 | ||

| 500 | - | - | ± 1.0 | ± 1.5 | ± 2.0 | ||

Proses Teknis:

Tungsten Powder → Isostatic Pressing → Bar Billet → Sintering → Semi-rampung bar → Forging → Swaging → Drawbench → Produk akhir → Inspeksi → Packing

Fitur

1.Titik leleh dhuwur lan resistance karat dhuwur

2. Efisiensi termal super

3. 99,95% Purity

4. Katon: salaka putih / abu-abu metallic luster Lumahing electrolytic polesan kabel tungsten bakal Gamelan, resik, abu-abu salaka karo logam luster.Kawat tungsten fitur formability banget, urip cendhak lan efficiency cahya nedha bengi.

Aplikasi

1. Ngasilake bagean sumber cahya listrik lan komponen vakum listrik;

2. Ngasilake unsur panas lan bagean refractory ing tungku suhu dhuwur;

3. Prodhuksi unsur panas digunakake ing vaccum metalizing utawa plating.